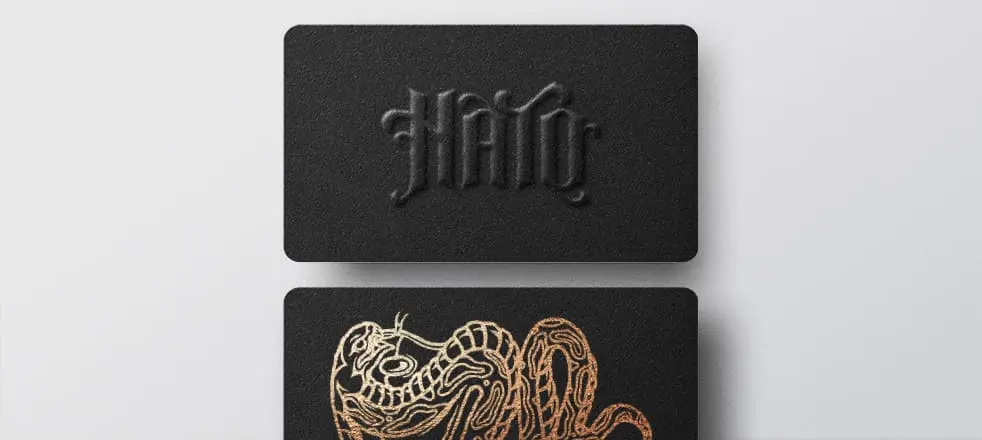

Embossing and debossing printing

Embossing printing is a process of obtaining a relief image on a product surface. Advantages:

- long service life;

- resistance to mechanical exposure;

- original design.

Thanks to this method, we get unusual images which please the eye and touch looking more expensive and attractive. There are several types of embossing:

Foil stamping - the foil is inserted between the material and the heated stamp. This type is considered the most eye-catching. There are two types:

- Hot stamping. The image is heated up and leaves an imprint on the material under pressure as the hot-melt adhesive layer of the foil melts.

- Cold stamping. The foil must contain a layer of adhesive that breaks down under UV. It can be used when the previous is impossible. Not suitable for highly absorbent bases.

Embossing makes the image rise above the surface. Special clichés are used to make the embossing tools.

With blind embossing, the image is pressed into the material using a blind cliché and a press. The impression is clear without paint. However, you can use foil to color the image. There are two types of blind embossing: Cold or hot, the choice depending on the base. Embossing is a great way to emphasize a brand highlighting the logo and other corporate attributes of the company’s identity. This post-print processing will help you give a unique design to any product.

Portfolio

Benefits

Services

Reviews

Our clients

Cooperation